Products

Alongside the production of turnkey systems, we build plant sections and supply single components, providing the necessary engineering service to determine the appropriate characteristics for each application.

Elements for the controlled combustion of biogas where the flame is completely contained inside the combustion chamber, which is dimensioned to guarantee a residence time >0.3 seconds with temperatures above 850°C. This type of burner is ideal for application in installations where low atmospheric emission limits are imposed.

High flare chimneys feature a vertical structure where the burner is situated at the upper extremity, ensuring the safety of the plant and protecting operative personnel from the combustion radiation. Combustors are available for a wide range of flow rates of the gas to be burnt.

We create systems for analysis, in particular to measure the percentages of methane, oxygen and carbon dioxide in biogas. A cell is available optionally for measuring sulphur dioxide. The biogas analysis panels are complete with apparatus guaranteeing operation safety from the possible presence of gases. Where required by the environmental authorities, we produce analysis panels for the control of the emissions, i.e. of the combustion fumes produced by the high-temperature flares.

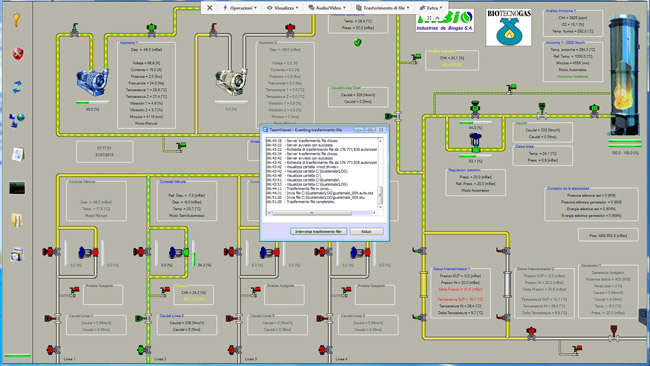

The monitoring of the plant by a PLC enables setting of given logics and a pre-alarm threshold, with retracing of past functioning and the handling of the data gathered through the installed instrumentation. At small-sized installations, where the investment must be limited, we install panels with PLC and touch-screen type interface. For installations where the acquisition and management of multiple parameters is important, we install specific SCADA systems.

For existing plants to be upgraded, including those produced by other companies, we supply and install the machinery and instrumentation necessary to restore optimal working conditions, both with regard to performance and concerning command and control. Each supply always includes the engineering service necessary to evaluate the need in detail and determine the suitable product.

We design and build plant sections for the dehumidification of the biogas to be used to power the motors for electricity generation or for upgrading processes. Form the engineering design of the system we proceed with the sizing of each component of the system: gas-water exchangers, gas-gas exchangers, demisters, refrigeration units and components of the hydronic circuit.

We design and create sections for the treatment of biogas, consisting of filters into which adsorbent materials – activated carbon – are introduced for the removal of hydrogen sulphide (H₂S) and siloxanes. The filters are made completely in stainless steel of different sizes depending on the flow rate and the allowable head loss. For larger-sized filters a raised walking platform is included, reachable by step irons, to enable loading of the carbon from the top.

Among the engineering activities, we determine the dimensions of the network for conveying biogas in HDPE pipes. We proceed to the welding and laying of the pipes and the necessary structures for the creation of capture wells, or slotted pipes and wellheads, and to the separation and handling of the condensation and leachate.

We build stations for regulating the collection of the biogas, consisting of HDPE structures pre-mounted on metal frames. Centralising the monitoring and regulation operations enables a more effective management of the collection network.

Need more informations?

Fill the form, we’ll answer you as soon as possible.